Low commodity prices, plummeting RIN values, and talk of potential trade wars are all factors hitting the US Agricultural Sector hard this year.

ESG & Industry Updates

Are Self Driving Trucks a Solution to Driver Shortages?

Posted by Ed Burke on May 25, 2018 11:46:00 AM

Are self driving trucks the long term solution to the driver shortage? Or will autonomous vehicles simply change the way drivers do their work every day?

Topics: autonomous vehicles, driver shortage

Winter 2017/2018 was a rough one for New England, particularly in terms of power outages. Generators have become an increasingly prevalent and important part of companies' Emergency Response Plans and as a fuel company, its important to look at how you handle the sometimes unpredictable surges in demand that covering your generator customers can cause.

Topics: Safety, Emergency Generator Program, Emergency Fuel

EPA Finalizes 2018 RFS Volume,Declines Obligated Party Change Proposal

Posted by Ed Burke on Dec 1, 2017 5:22:05 PM

Yesterday (November 30th) the EPA finalized renewable volume obligations for the RFS for 2018 and the RVO levels for 2019.

Topics: EPA Mandate, RINs, Biofuels, Cellulosic Ethanol, EPA, RFS

This August, Tesla employees receieved the first deliveries of the much anticipated Tesla Model 3. By all accounts, the Model 3 was met with fully positive feedback upon test driving. If you recall, the Model 3 got half a million pre production money down "reservation" orders in the absence of a test drive or really any standard marketing campaign in place. (For a refresher on the Model 3 debut, read this: Tesla's Model 3 Debut Stuns Industry)

Topics: EV Charger, electric vehicles, tesla

Air Conditioning Goes Global - but Environmental Cost Could Be High

Posted by Ed Burke on Aug 15, 2017 9:05:00 AM

Topics: Oil & Energy Magazine, Climate Change, Carbon Emissions, Air conditioning, HFCs, Montreal Protocol, Kigali Amendment

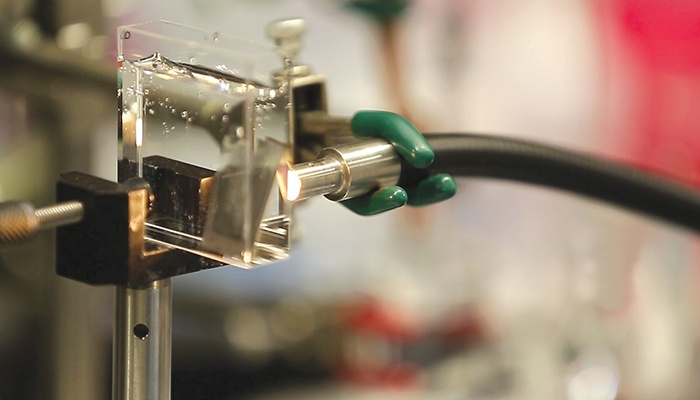

"Bill Gates has said that to solve our energy problems, someday we need to do what photosynthesis does, and that someday we might be able to do it even more efficiently than plants...That someday has arrived" - David Nocera, Harvard University

Topics: Oil & Energy Magazine, Solar, Carbon Emissions, bionic leaf

Clean Power Plan Rollback - Serious Issue or Symbolism?

Posted by Ed Burke on May 31, 2017 10:25:38 AM

This March, President Trump signed an executive order to potentially roll back the Clean Power Plan, as part of a broader order regarding Energy Production & Independence in the US. The order directs the EPA to review the ruling and make a determination on whether to "rescind, repeal, or revise".

Topics: EPA, clean power plan

A number of start ups are seeking to replace your trip to the gas station with the tap of an app. Much in the same fashion you would use a ride share service, or a mobile glass replacement service, these apps would allow you to request a fill up via smartphone from your home, office, or wherever is convenient.

Topics: Oil & Energy Magazine, Technology

The Struggle is Real for Regulating Autonomous Vehicle Safety

Posted by Ed Burke on Mar 23, 2017 3:00:00 PM

Self-Driving vehicles (or AV's - autonomous vehicles) are the undisputed next frontier in consumer transport technology. Automakers, it appears, are anxious for Federal Guidelines to be put in place in order to tailor their roll outs, and be assured that they are in compliance with safety expectations, as well as in order to circumvent the mess of State's adopting their own patchwork regulations in leiu of uniform federal regulations.

Topics: Safety, Technology, AVs

Subscribe to Email Updates

Recent Posts

Posts by Topic

- Carbon Emissions (32)

- Climate Change (27)

- Oil & Energy Magazine (24)

- renewable energy (24)

- EPA (19)

- Biden Administration (14)

- Massachusetts (14)

- decarbonization (12)

- EPA Mandate (11)

- RFS (11)

- natural gas (11)

- Keystone XL (10)

- Solar (10)

- Biodiesel (9)

- Biofuels (9)

- Clean Energy (8)

- Energy Independence (8)

- methane (8)

- Energy Infrastructure (7)

- Ethanol (7)

- Safety (7)

- Cellulosic Ethanol (6)

- Emissions (6)

- RINs (6)

- Fracking (5)

- US Crude Exports (5)

- electric vehicles (5)

- maine (5)

- offshore wind (5)

- Biodiesel Tax Credit (4)

- EV Charger (4)

- Mass DOER (4)

- Technology (4)

- TransCanada (4)

- Utility Rates (4)

- massachusetts biodiesel mandate (4)

- obama (4)

- CRUDE (3)

- E85 (3)

- Emergency Fuel (3)

- Massachusetts Clean Cities (3)

- Waste Feedstock Biodiesel (3)

- clean power plan (3)

- environmental justice (3)

- ev (3)

- paris accord (3)

- remote tank monitoring (3)

- tesla (3)

- AVs (2)

- Bioheat (2)

- Carbon Capture (2)

- Commodities (2)

- Congress (2)

- Customer Service (2)

- DOT (2)

- EIA (2)

- Emergency Generator Program (2)

- Hurricane Sandy (2)

- IMO 2020 (2)

- MIT (2)

- Marinas (2)

- New York (2)

- Refinery Closures (2)

- TCI (2)

- US Energy Boom (2)

- autonomous vehicles (2)

- battery (2)

- china (2)

- coal (2)

- driver shortage (2)

- emergency response (2)

- environment (2)

- ferc (2)

- fuel management (2)

- geothermal (2)

- hydro-electric (2)

- hydrogen (2)

- national grid (2)

- net metering (2)

- power plant emissions (2)

- railcar regulations (2)

- API (1)

- Air conditioning (1)

- Baiji Refinery (1)

- Blend Wall (1)

- Brent Crude (1)

- Brent vs WTI (1)

- CFCs (1)

- Cell Phone Policy (1)

- Election Results (1)

- Energy Efficiency (1)

- Environmental Impact Study (1)

- Environmentally Friendly Products (1)

- Ethanol Tax Credit (1)

- FEMA (1)

- Fiscal Cliff (1)

- Gas Tax (1)

- Gasoline Supply Crunch (1)

- HFCs (1)

- Hazmat (1)

- Heat Tax (1)

- Highway Trust Fund (1)

- Holyoke (1)

- Hybrid (1)

- ISIS (1)

- Inflation Reduction Act (1)

- Iraq (1)

- Kigali Amendment (1)

- MOC (1)

- Market analysis (1)

- Mayflower (1)

- Montreal Protocol (1)

- NORA (1)

- Natural Gas Pipeline Explosion (1)

- New Jersey (1)

- Oil Barrel Tax (1)

- Pegasus Pipeline (1)

- Propane Autogas (1)

- Safe Driving Policy (1)

- Stimulus (1)

- Syria (1)

- Tank Truck Safety Training (1)

- Tax Increases (1)

- Tier 3 Gasoline Standard (1)

- Times Square (1)

- VEEP (1)

- Workplace Risk (1)

- algonquin pipeline (1)

- alternative energy (1)

- altwheels (1)

- astm (1)

- bionic leaf (1)

- bitcoin (1)

- boston (1)

- clean air act (1)

- covid-19 (1)

- electricity rates (1)

- energy storage (1)

- eversource (1)

- export ban (1)

- fuel efficiency (1)

- fuel marketers news (1)

- gas leaks (1)

- heating oil (1)

- hurricane harvey (1)

- inflation (1)

- irving oil (1)

- marketing (1)

- net-zero (1)

- ozone (1)

- photovoltaic (1)

- pilot program (1)

- pipeline (1)

- propane (1)

- renewable natural gas (1)

- russia (1)

- sanctions (1)

- senate (1)

- shale (1)

- social media (1)

- social media for business (1)

- solid state battery (1)

- space (1)

- tablets (1)

- tennessee pipeline (1)

- ukraine, (1)

- value added services (1)